Circular Economy

20/07/2023 |

Plastics Circular Economy 2023 - an Update

Current challenges and aspired goals

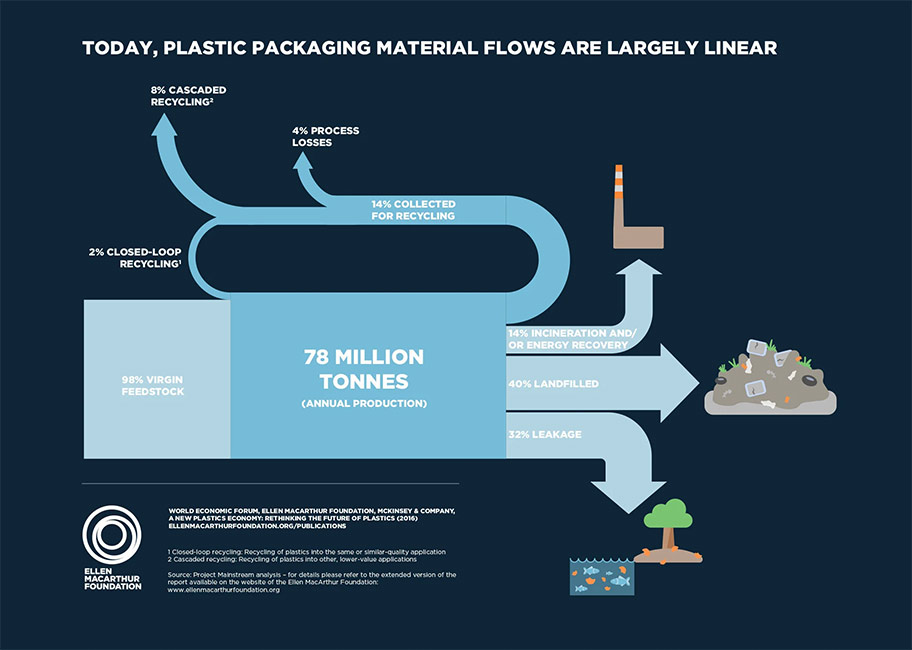

The current state of the plastic circular economy in Europe is still far from the targets set, despite the EU's efforts. Every month, each European produces an average of three kilograms of plastic waste. In 2020 alone, 450 million tons of plastic were produced worldwide, according to OECD data. This amount could triple by 2060. Although the EU is setting "recycling records," only about 40% of end-of-life plastic in Europe is actually recycled. The rest is incinerated or ends up in waterways and soil. Recent research by Investigate Europe shows that there is still a strong imbalance within the EU. Some European countries still rely mainly on disposal and do little recycling.

To create a functioning system without financial loss, plastic waste or pollution, a systemic approach is needed: a complete redesign of how plastics are produced, used and reused, and a redesign of the underlying system.

The Ellen MacArthur Foundation, a nonprofit organization that works to create a circular economy, has identified six key points that comprise the vision of a circular economy for plastics:

- a top priority is the elimination of problematic and unnecessary packaging through redesign, innovation and new delivery models.

- in addition, single-use packaging should be reduced through reuse models.

- all plastic packaging should not only be 100% reusable, recyclable or compostable…

- ...but also actually reused, recycled or composted.

- a clear separation between the use of plastics and the consumption of finite resources is needed.

- all plastic packaging should also be free of hazardous chemicals.

Possibilities for optimizing the recycling quota as well as the use of recyclates

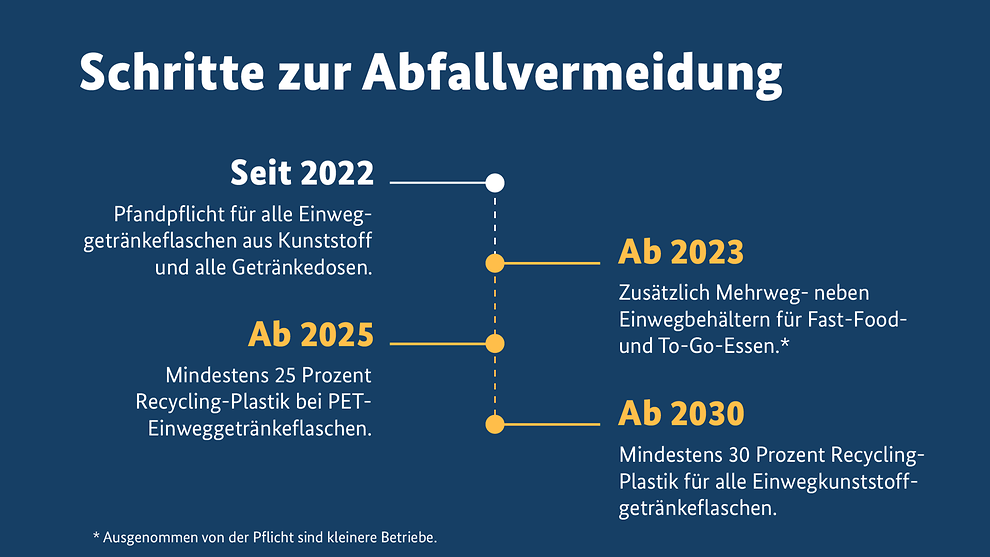

A frequently discussed solution for improving plastic recycling is a statutory minimum quota that prescribes what proportion of plastic waste must be recycled. This would lead to more sorting and thus higher availability of recycled material. Another measure would be a statutory minimum quota for the use of recyclate in certain plastic products. Currently, the EU and Germany only have recycling quotas for disposable PET bottles. From 2025, these must consist of at least 25 percent recycled material, and from 2030, 30 percent. Germany has already cracked this hurdle and, with 40% recycled content in PET bottles, is a pioneer throughout Europe. In November 2022, the European Commission now also proposed a mandatory quota for recycled material in all new plastic packaging.

Extending deposit systems to other product groups could also increase the recycling rate. Deposit systems make it possible to cleanly separate plastic waste and produce high-quality recyclate.

But achieving the EU's goals on the road to a circular economy will require more than just quotas. For example, from the outset, each package must be intelligently designed for recycling in accordance with strict specifications. In addition, high recycling quotas must be implemented not only in Germany but throughout the EU in order to obtain sufficient recyclate for food packaging. In addition, new recycling technologies should also be approved more quickly for the food sector.

Quelle:

https://www.bundesregierung.de/breg-de/schwerpunkte/klimaschutz/mehrweg-fuers-essen-to-go-1840830

Successes to date

While there is still a long way to go, efforts to promote the recycling of plastic packaging are already bearing fruit. In 2021, a mechanical recycling rate of 65.5% was achieved in Germany, an increase of 5% compared to the previous year.

This even exceeded the increased recycling target of 63% that has been in place since 2022. Since the introduction of the Packaging Act in 2019, the recycling rate has increased by 55%.

The design-for-recycling approach is also showing initial success. According to a study by GVM (Gesellschaft für Verpackungsmarktforschung - Society for Packaging Market Research), 74% of plastic packaging collected close to households is readily recyclable. In 2016, the figure was still 66%. In order to maintain this trend, the German federal government, for example, is going one step further with the expansion of the Packaging Act. As a result, all single-use plastic beverage bottles and all beverage cans have been subject to a deposit since the beginning of 2022. To counteract the tons of packaging waste generated every day by take-away disposable packaging, catering businesses will also have to offer reusable containers for take-away food and drinks from this year onwards.Various systems have already been established for reusable coffee-to-go cups. Waste exports to China and Southeast Asia have also fallen significantly since 2016 due to the EU-wide export ban on plastic waste that is difficult to recycle.

According to a study by GVM and the Ifeu Institute for Energy and Environmental Research in Heidelberg entitled "The contribution of recyclable packaging to the climate neutrality target in 2045", greenhouse gas emissions resulting from raw material production, packaging production, distribution, and disposal and recycling could be reduced by 94% by 2045. According to the study, packaging consumption in Germany peaked in 2021 and will decline continuously in the future. At the same time, the use of recycled materials will increase.Tense situation in the plastics industry

Problems of plastics processors

Weak demand, high energy costs and a shortage of skilled workers are currently (May 2023) worrying plastics processors. Almost one in five companies has reduced its production to a significant extent. The outlook for the coming months is also bleak, with more than one-third of companies expecting to reduce their workforce in the industry. According to the IK (Industrievereinigung Kunststoffverpackungen e.V.), the main reason for the current crisis is weak demand for plastic packaging. The falling raw material prices since March have had a negative impact on the entire plastics recycling industry. Plastics processors, for example, face the problem that they would have to buy expensive recycled material to meet quotas. However, profitability is suffering as a result.

Problems of plastics recyclers

Due to the ongoing price war, plastics processors often opt for the cheapest offer and increasingly use virgin material, which in turn puts plastics recyclers in a bind, as the Fachverband Kunststoffrecycling at bvse explains. Demand for used plastics is so low that in some cases production has to be restricted or even shut down, it says. Stocks of regranulates, regrinds and compounds are also growing steadily. Due to weak demand, the customer markets are taking up too little secondary material. The situation in the PET recycling sector is particularly precarious.

Conclusion

Overall, despite the efforts of the EU, the plastics circular economy in Europe is still far from the targets set. The recycling rate is only about 40%, while the production of plastics continues to increase. Fundamental changes in the manufacturing, use and reuse process of plastics are needed to achieve sustainable and environmentally friendly use. Legal minimum quotas for recycling and the use of recyclates, as well as the expansion of deposit systems, can be helpful measures. Despite some progress, there is still a challenge to create a functioning system without financial losses, plastic waste or pollution.

A systemic approach and increased use of innovative sorting technologies and solutions are needed to ensure competitiveness and at the same time profitability of recyclers. This is a prerequisite for improving recycling rates, promoting the use of recyclates and realizing the long-term goal of a circular economy for plastics.